A full-scale prototype for a droneport has been built on site in the Arsenale in Venice and will be unveiled at a Press Preview during the 15th International. The proposal is to create a network of droneports to deliver medical supplies and other necessities to areas of Africa that are difficult to access due to a lack of roads or other infrastructure and the ambition is that every small town in Africa and in other emerging economies will have its own droneport by 2030. The pilot project – which will be launched this year – is based in Rwanda, a country whose physical and social geography poses multiple challenges. The initial plan for three buildings, to be completed by 2020, will enable the network to send supplies to 44 per cent of Rwanda.

Subsequent phases of the project could see in excess of 40 droneports across Rwanda, and the country’s central location could allow easier expansion to neighbouring countries such as Congo, saving many thousands more lives. Jonathan Ledgard, Founder of the Pioneering Redline Cargo Drone Network, a concept he developed at the Swiss federal institute of technology in Lausanne (EPFL), approached Norman Foster with the concept because of his combination of airport design experience and knowledge of flight as a pilot of sailplanes, helicopters and aircraft. Foster then shared the challenge with his colleagues Narinder Sagoo and Roger Ridsdill Smith at Foster + Partners. Working with their teams, the basis of a modular vaulted system evolved. It has fallen to The Norman Foster Foundation to advance it beyond early feasibility stage and has led to the present team to design, engineer and implement the project through to a built reality.

Cargo Drones

Cargo drone routes have utility wherever there is a lack of roads. Just as mobile phones dispensed with landlines, cargo drones can transcend geographical barriers such as mountains, lakes, and unnavigable rivers without the need for large-scale physical infrastructure. Just a third of Africans live within two kilometres of an all-season road, and there are no continental motorways, almost no tunnels, and not enough bridges that can reach people living in far-flung areas of the continent. It would require unprecedented levels of investment in roads and railways to catch up with the exponential growth in Africa’s population, which is set to double to 2.2 billion by 2050.

An ‘infrastructural leap’ is essential using drone technology and clean energy systems to surmount the challenges of the future. The specialist drones can carry blood and life-saving supplies over 100 kilometres at minimal cost, providing an affordable alternative that can complement road-based deliveries. Two parallel networks would operate services, the Redline using smaller drones for medical and emergency supplies; and the commercial Blueline that would transport crucial larger payloads such as spare parts, electronics, and e-commerce, complementing and subsidising the Redline network.

The Droneport

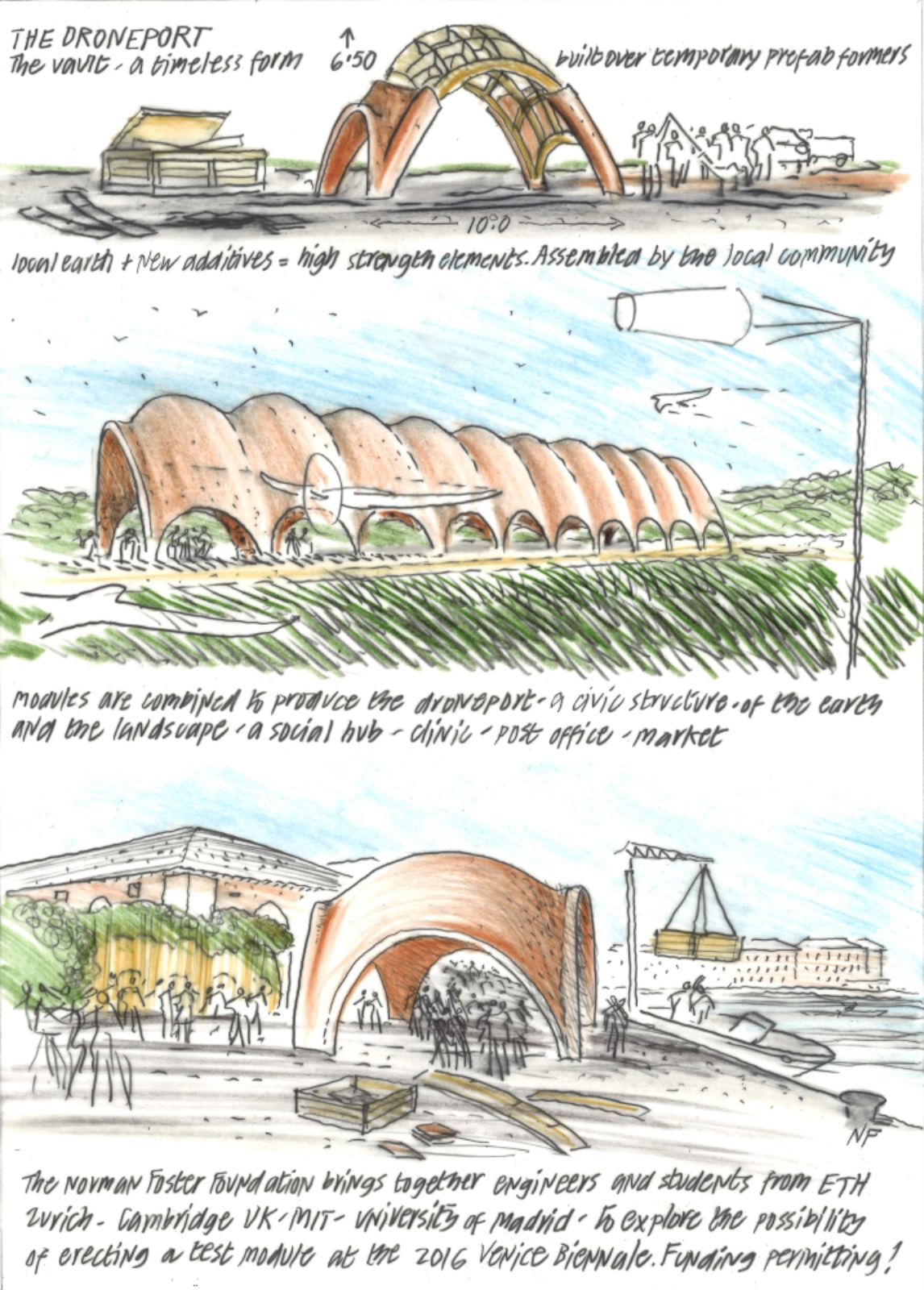

The Droneport offers a new typology for a building, which it is hoped, will grow into a ubiquitous presence, much like petrol stations have become dispersed infrastructure for road traffic. The proposal will have a strong civic presence, based on sharing and multiple uses. It allows for safe landing of quiet drones in a densely packed area, and includes a health clinic, a digital fabrication shop, a post and courier room, and an e-commerce trading hub, allowing it to become part of local community life. The project is an evolution of Norman Foster’s previous experience in building airports, as well as earlier lunar building studies conducted in association with the European Space Agency.

Just as the structures designed for the moon use a minimal inflatable framework and 3-D printed lunar soil, the Droneport is imagined as a ‘kit-ofparts’ where only the basic formwork and brick-press machinery is delivered to site, and the raw materials, such as clay for bricks and boulders for the foundation, are locally sourced, reducing material transport costs and making it more sustainable. The central idea is to ‘do more with less’ and the vaulted brick structure with a minimal ground footprint, can easily be put together by the local communities. Multiple vaults can also link together to form flexible spaces based on demand and needs of the particular place, and the evolution of drone technology. The Droneports will also be manufacturing centres for drones, generating employment opportunities for the local population. By giving the local people the construction knowledge, the project seeks to leave a legacy that will initiate a change that is bigger than the building itself.

The Norman Foster Foundation Pavilion

The creation of a Biennale pavilion was made possible by The Norman Foster Foundation which brought together professors and students from five universities across Europe, the UK and America along with a foundation for the building industry and its related research laboratory. Its theme fits perfectly with Alejandro Aravena’s motto “Reporting from the Front”. Its construction in Venice was filmed to serve as a model for replication by local communities in emerging economies such as Africa, South America and parts of Asia. Although initially a response to the droneport, the construction system is applicable to a wider range of needs markets, schools and medical facilities for example.

Its location at the end of the Arsenale is symbolic as the gateway to a newly opened public park. The possibility of it remaining as a permanent legacy is now under consideration. The colouration of the earth-based products, which were specifically made for the project, are a careful match with the historic buildings which surround it. It would be a timeless addition to the Biennale site and virtually maintenance free. The project has been realised by The Norman Foster Foundation on a very tight timescale, 6 months overall, 4 weeks on site – made possible by the close links between the engineer partners of ODB and their universities. John Ochsendorf teaches at MIT, Matthew de Jong at Cambridge and Phillipe Block, with his research group at ETH Zurich.

Jonathan Ledgard, originator of the drone port concept and founder of Redline, developed the idea at EPFL in collaboration with the Laboratory of Intelligent Systems (LIS) of Dario Floreano. An interim feasibility study involved the construction of a half size vault at the Polytechnic University of Madrid headed out by Professor Santiago Huerta. This was realised by a Master Mason, Carlos Martín Jiménez, attached to the project with two students from MIT – Sixto Cordero and Luisel Zaya. The same team, expanded with Segundo Victor Simba and Luis Alfonso Tituania Male moved on to Venice to create the present pavilion. The Madrid exercise enabled the combined resources of the LafargeHolcim Foundation for Sustainable Construction and their research laboratory in Lyon to develop a special earth-based product for the project. 18,000 customised elements have been produced for the pavilion.

The challenge was to ensure a compressive strength of at least 10 MPa whilst minimising the weight and size of each brick. The prototype vault comprises two outer layers of this custom product with an inner layer of traditional tiles from Valencia. The special product is of stabilised earth – a reliable, affordable and environmentally friendly building material. Compared to traditional burnt clay bricks, they do not require intensive use of fuel to achieve their performance. LafargeHolcim developed a naturally cured building block made of compressed earth and cement termed ‘Durabric’. The mix design for the droneport was optimised in close cooperation with the Block Research Group at ETH in Zurich and MecoConcept in Toulouse.

The Norman Foster Foundation has collaborated with the Studio Olafur Eliasson and Little Sun to explore the potential of a new building component called ‘SolarBrick’, which could be incorporated into the structure of the droneport vaults. The ‘SolarBrick’ will have solar cells on its outer surface, charging a long-life battery and then powering a LED lamp on the inner surface. The units, which could be 3D printed within the droneports themselves, could become common place in local buildings, providing light where electricity is scarce. Source and images Courtesy of The Norman Foster Foundation.