The Macquarie University Incubator was designed to respond to the diverse and changing needs of its occupants, as well as two key aspects that informed the design of the space; a relocatable building and a short timeframe for its implementation. Timber was selected as the main construction material for its capacity to be beautifully engineered, swiftly fabricated to high quality, and for its potential for future dis-assembly and relocation.

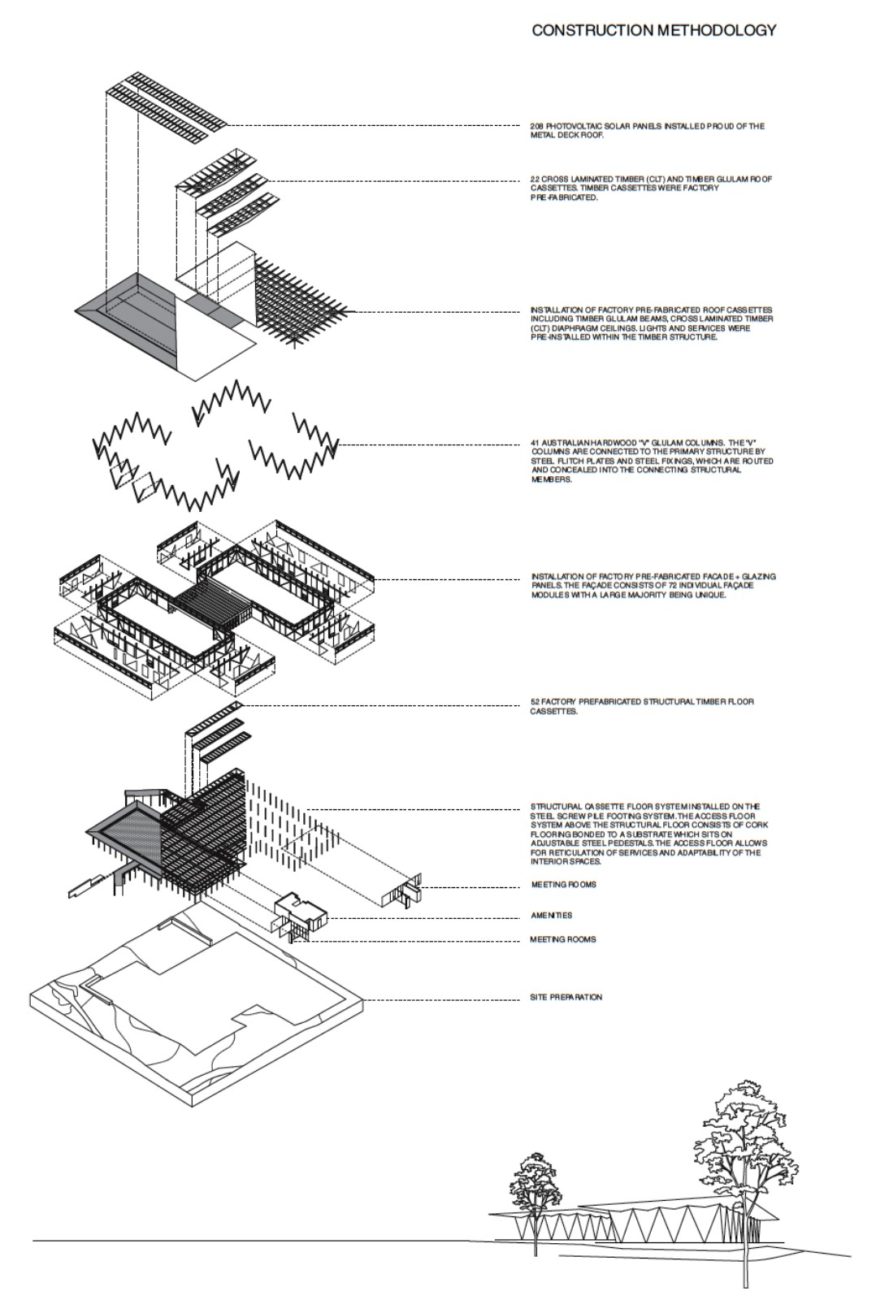

The resulting building was completed within five months of construction commencing, and despite flexibility and relocation being a strong factor of the original design brief, the Incubator has become so well loved that it’s likely it will now remain permanently in its current location. Various timber species were used throughout, including a ceiling diaphragm of cross laminated timber, large span laminated veneer lumber beams and glulam V columns, as well as spotted gum hardwood and cork for the interior floor surfaces, and plywood for the external walls.

Working with partners including Lipman and StrongBuild, these materials allowed us to take an innovative approach to design, while offering potential for a very high degree of reuse should the building ever be relocated. The Incubator was conceived as a pair of pavilions, each with flexible layouts that lend themselves to the future adaptations and functions of the start-ups inside. A strong driver was the need for collaboration and interaction between individual start-ups and with each other, in addition to privacy for each start-up to operate as its own business.

Sustainability Initiatives/Features

The mechanical solution is designed to benefit from external conditions, providing assisted natural ventilation to the spaces for more than 60% of the year as required, and tempering incoming air in peak seasons to maintain a comfortable environment. This is aided by the building’s form with the overhanging roof and solid façade elements minimising external solar and heat gains. Other initiatives include the installation of photovoltaic panels on roof to offset 60% of energy use, and rainwater run-off being captured by the landscape for irrigation.

The roof is constructed with timber glulam beams, glulam columns and CLT diaphragms. The timber roof cassettes and floor cassettes system increase productivity, reduce site construction times and improve operating safety during the construction process. Steel was used in place of concrete for the foundations, as the superstructure is relatively light. Timber floor beams are directly connected to steel screw piles to form the foundation structure. As steel can easily be reused, this is environmentally friendly and benefits cost and construction time. Source by Architectus.

- Location: Sidney, Australia

- Architect: Architectus

- Town Planner: Ethos Urban

- Structural / Civil: ARUP + TTW

- Facade Engineer: TTW

- Mechanical / Electrical: ARUP

- Hydraulics / Fire Services: ARUP

- Acoustic Engineer: ARUP

- Quantity Surveyor: WT Partnership

- Landscape Architect: Aspect

- Project Manager: Root Partnership

- Contractor: Lipman

- Client: Macquarie University

- Total NLA: 940 m2

- GFA: 1360 m2

- Construction completion: August 2017

- Official opening: September 2017

- Photographs: Brett Boardman, Courtesy of Architectus