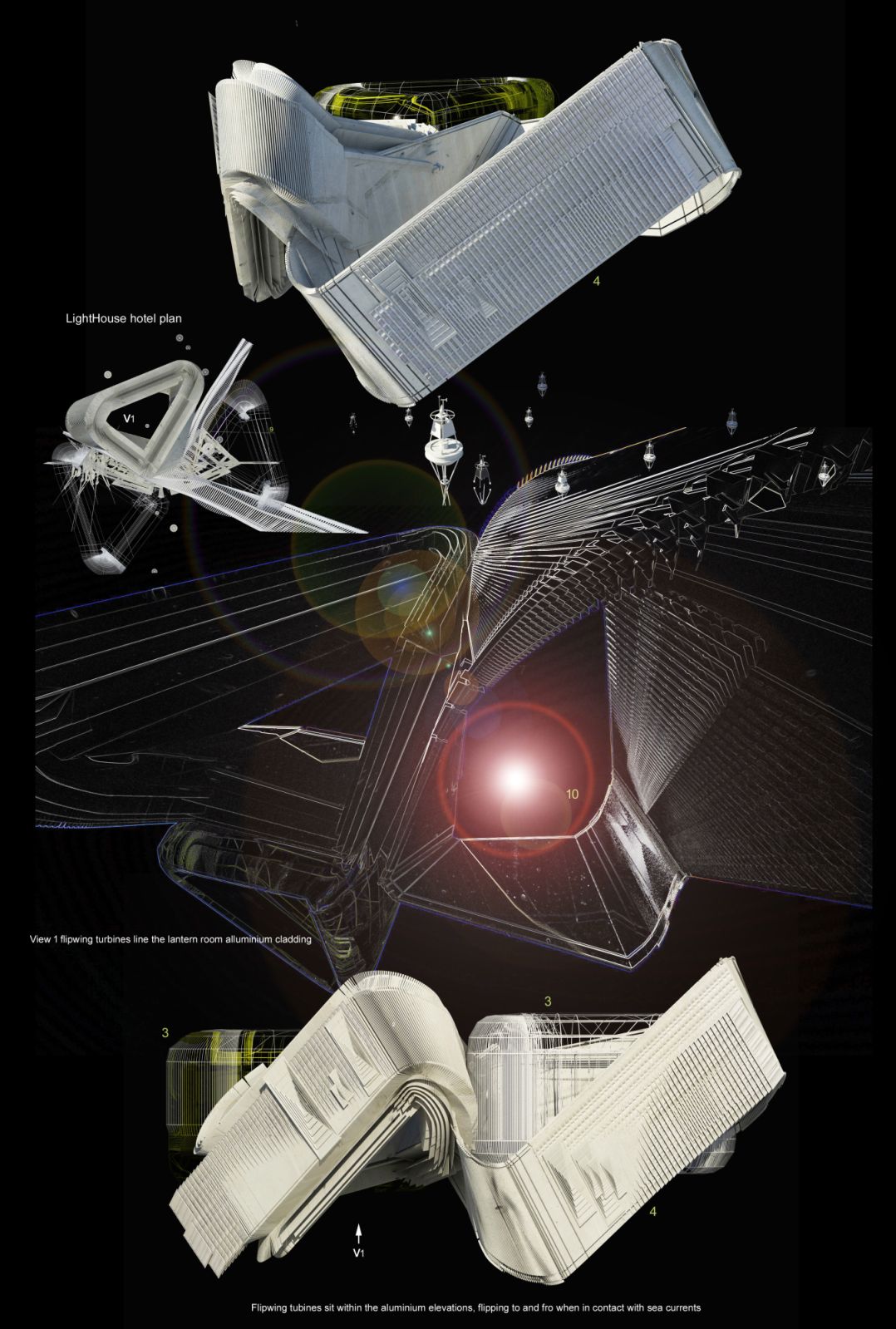

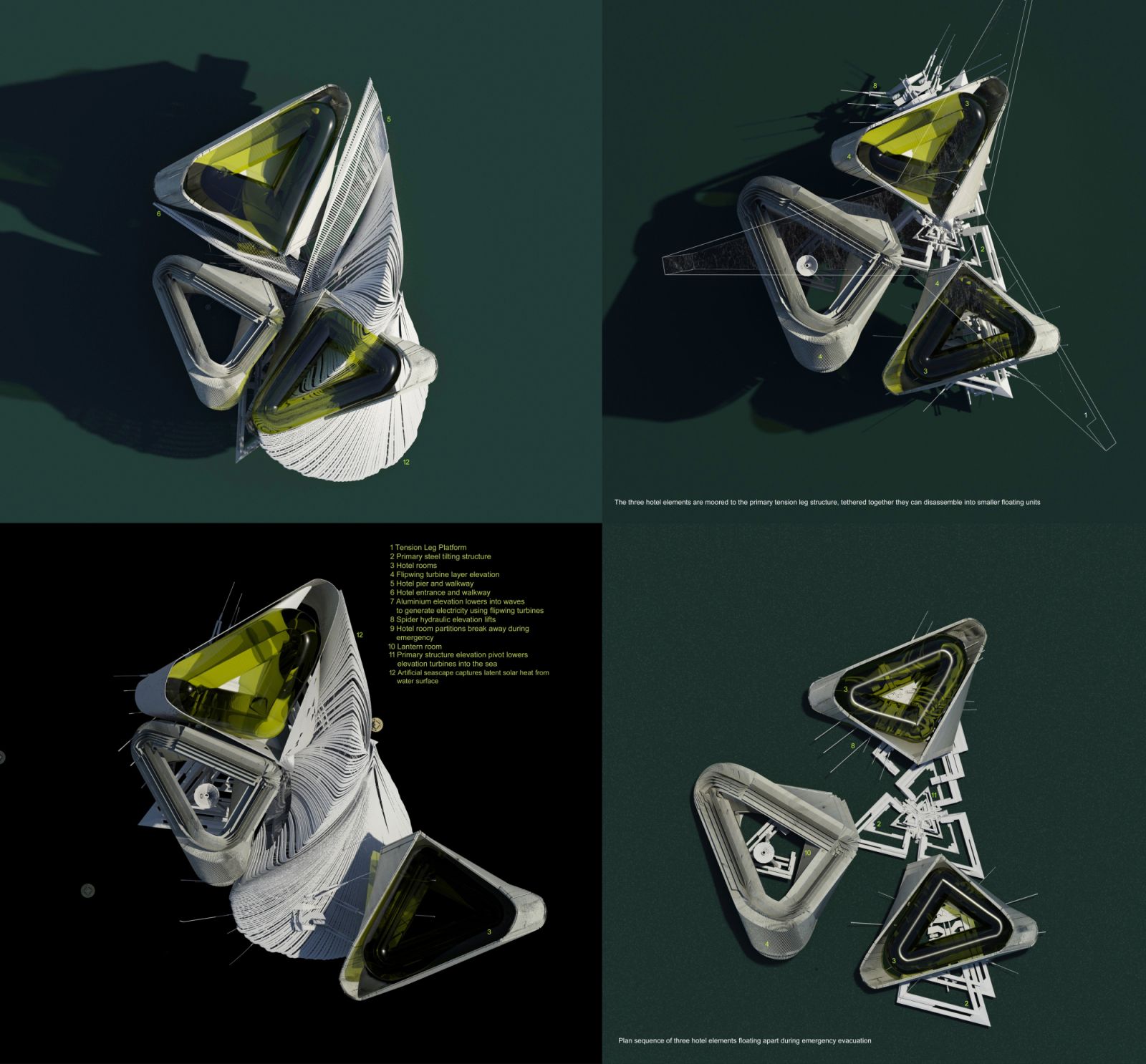

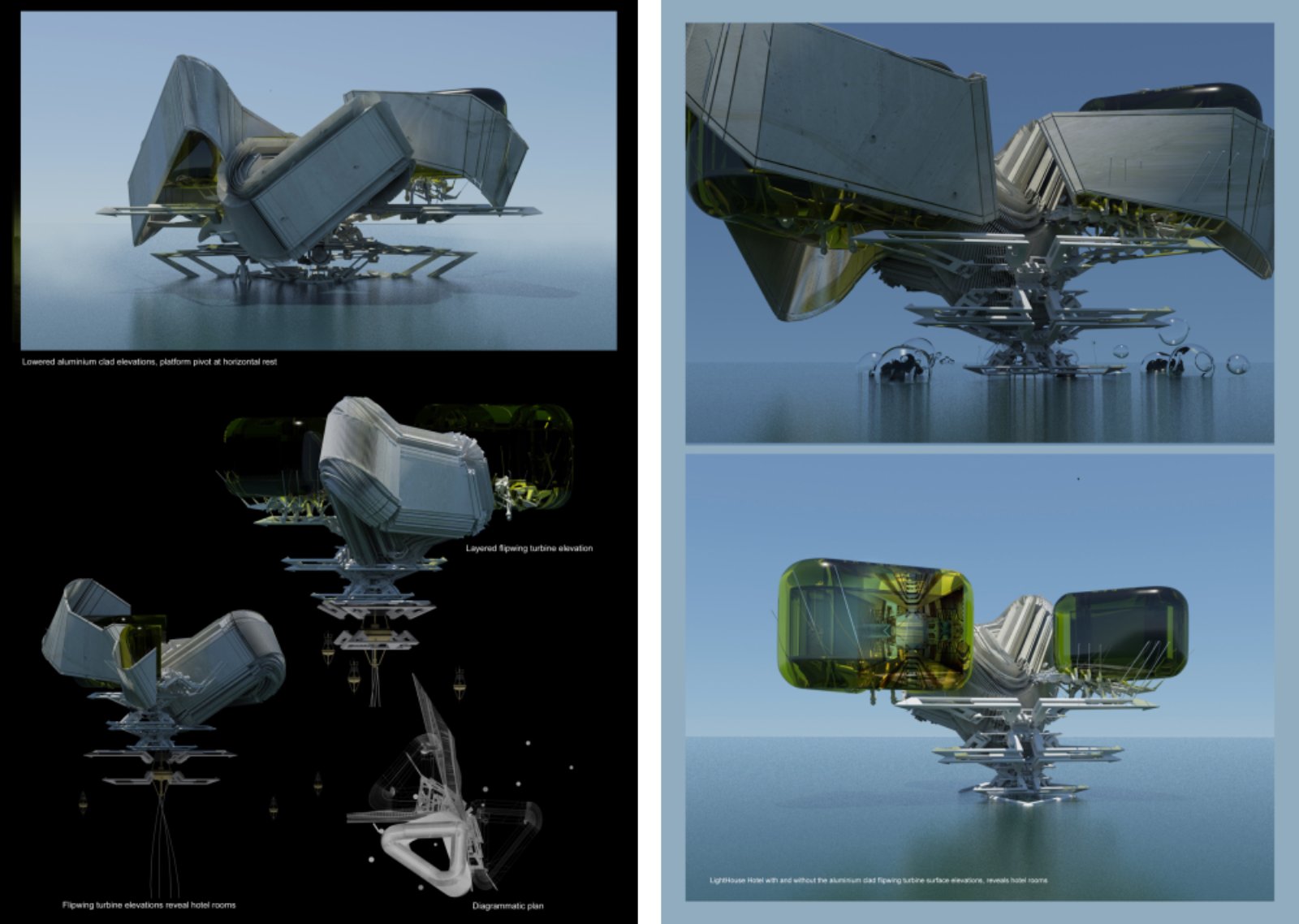

The project brief is to design an off shore lighthouse hotel. The design criteria addresses renewable energy by harnessing wave energy to generate electricity when lowering parts of the hotel’s three separate elevations into the seawater. The design is made up of three elements that contain the living and social areas of the hotel and three elevations wrap around the hotel, they are suspended from a hydraulic lift and primary structure. The three layered aluminium surfaces enclose flipwing turbines which produce electrical energy when they are lowered into the sea, the water crashes against the aluminium panels and flips/turns the hydropower turbines that are sandwiched between the layers of aluminium clad surfaces.

Flipwing turbines flex as water flows over them. The hotel is fabricated from a series of partly inflated, moulded ETFE membrane sections, these lightweight yet durable airlock sections split apart and float in the event of a rogue wave or emergency. The elevations release the stored sea water back through the embedded turbines. Lifting the turbine elevations out of the water minimizes salt water corrosion, all the materials used are easy to obtain and replace, also the cladding comes in modular format making it easier to repair. The lighthouse acts as a hydropower plant, the raised elevations can store potential energy by trapping sea water within the layers and releasing it when required to generate electricity.

The different heights of water reservoir require water to be pumped into the elevation/cladding reservoirs during periods of low demand to be released for generation when demand is high or system generation is low. The lighthouse hotel reduces it’s water consumption by storing rainwater, desalination of sea water, grey-water systems and reclaimed water. The aluminium clad elevation elements are lowered into the water in order for the turbines to generate electricity to run the lighthouse, and for the desalination filters, any surplus energy is stored. Cassion foundations and gravity anchor the tension leg platform so that there is no vertical movement only horizontal displacement which is kept at a minimum, the platform is held in place by steel tension cables which are embedded into the ocean floor.

Oil rig construction has inspired the overall structural design of the lighthouse. During storms, the suspended elevations are lowered enough for the emitting light to project over the sea. An increasing number of lighthouses have been decommissioned because of their obsolete technology/functional obsolescence whilst the remaining lighthouses are still in use in case of GPS and electronic navigational failures. Programmatically hotels are becoming increasingly regenerative/continuously reinventing themselves and the hospitality experience, in order to avoid becoming typologically obsolete due to ever changing technologies, functions and tastes/trends.

This scheme attempts to cross-programmatically ensure that sustainability and renewable energy are at the forefront of the design criteria. Hotels have a high design turnover and can accommodate more experimental design approaches catering to individuals who want to experience an unique getaway, by integrating/ function to the building with an environmentally minded clientele, the hotel offers volunteer opportunities for guests to engage and appropriate with biodiversity and community as part of the experience. The lantern room is housed at the top of the hotel, it is revealed when the elevations lower during storms, the Fresnal glass lantern stretches out over the entire floor creating an illuminated glass canopy lobby.

The refracted light intensifies as it reflects into and out from it’s surroundings. The hotel is located off the coast of mainland South Korea near island of Jeju, reached by boat in water depths between 1500 and 7000 ft, it is a functioning power plant. South Korea has a large number of off-shore wind turbine farms, since 2006 South Korea has invested in vast areas and large sized wind renewable energy turbines. Industrial and ship building contractors have been making the wind turbines and I believe that the ship building industry along with marine engineering should contribute to building processes that focus on harnessing renewable energy.

The tension leg platform works in the same way as a taut moored buoy. The tethered buoyant structure is a large, semi-submersible floating vessel, which uses a heavy gravity vacuum anchor to fasten it to the seabed. Tension force is maintained in these vertical cables by adjusting the buoyancy of the floating platform, ensuring positive tension at all times. This method reduced marine response in the platform to effectively zero in vertical terms, and very little in horizontal terms. Horizontal drift can be further reduced as necessary. By using buoyance against a tension mooring system, this allows the use of a semi-submersible floating platform, which can carry an additional load by balancing this out by increasing the buoyancy.

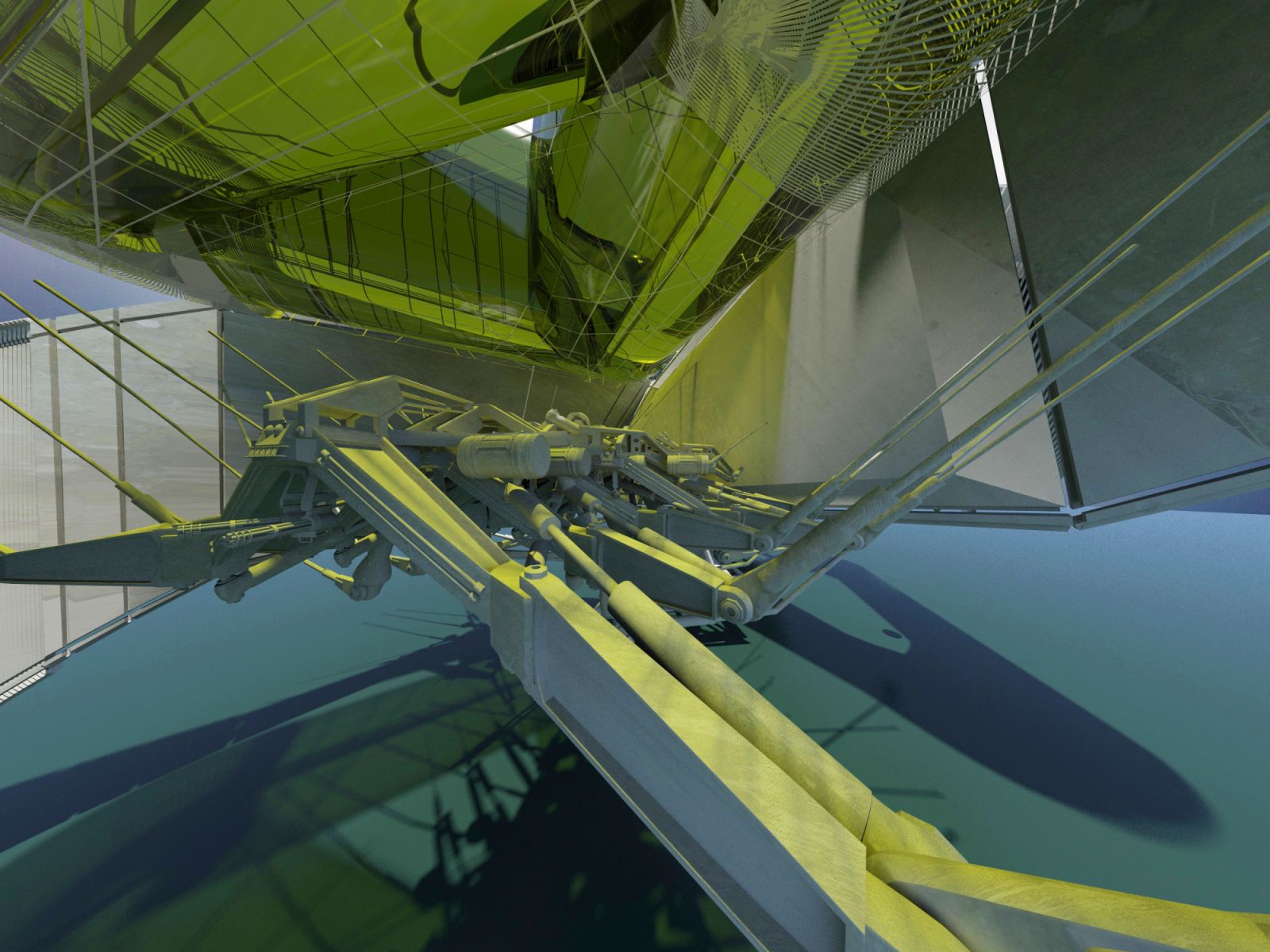

The turbine elevation movements are choreographed by the pivot wheel hydraulic frame section. A pivot wheel is bolted to the main primary structure in order to reduce fatigue stress caused by changing loads along the structure, due to movement and load redistribution. The pivot wheel moves and tilts lowering and revolving the elevations according to wind and wave direction. Lifting the turbine elevations out of the water minimizes salt water corrossion, all the materials used are easy to obtain and replace, also the cladding comes in modular format making it easier to repair. The turbines lay flat against the elevation when inactive, they are robust and cheap by comparison to the propellor turbines, but perhaps not as efficient. Source and images Courtesy of Margot Krasojevic.

Image © Margot Krasojevic

Image © Margot Krasojevic

Image © Margot Krasojevic

Image © Margot Krasojevic

Image © Margot Krasojevic

Image © Margot Krasojevic

Image © Margot Krasojevic

Image © Margot Krasojevic

Image © Margot Krasojevic

Diagram

Flipwing Turbines

Lowered and raised Elevations

Lowered wave pistons

Concept

Sections

Sections

Sequence Sections and Views